LOTUS GOES V8

Next Tuesday, Lotus will unveil a new V8 engine

to power its Esprit into the next century.

A new Lotus V8 engine makes its debut this Sunday, at a

four-hour endurance race at France's Paul Ricard circuit, in a works Esprit.

Two days later, it appears in road going form at the Geneva motor show.

Lotus will be holding its breath at both: this is an engine it needs, and

needs to succeed.

The bald figures are straightforward enough: twin turbos,3.5

litres, quad cams, four valves per cylinder, all-aluminium casing, 350 bhp

at 6500rpm and 295lb ft of torque at 4250rpm, The reasons for its existence,

however, are not. More of which in a moment.

Lotus has looked seriously at building V8 engines since

the late '70s, when a four-litre unit, (codenamed 909) was conceived, mostly

for the proposed Etna supercar. Ten years later, for General Motors, it

designed and developed the LT5 V8 for the Corvette ZR1, then, as a potential

alternative to GM's own North Star engine, a transverse V8.

However, this new V8, Project 618 as it known in-house, is initially for Lotus's own use. So how and why did it come about ?

'The bald figures are straightforward:

twin turbos, 3.5 litres, quad cams, 350bhp and 295lb ft'

A new engine was needed for the Esprit, of course. Although claiming exemplarily good emissions by current norms, its turbocharged, 2.2-litre four-cylinder is basically 25 years old now, and would have required much development to meet impending legislation, not least US emission-based on-board diagnosis (OBD II) requirements.

However, Project 618 also came about

as a show case, demonstrating what Lotus can design and make, and how quickly

it can do it. From conception to production, this engine took 27 months,

which compares, in an example typical for the industry, with about three

years for Ford of Europe to bring its 1.1 Litre Zetec-SE engine to market.

|

Small enough to fit a Mondeo, stiff Lotus V8 uses

exotic high-silicon aluminium alloy block and long Rover KV6-style

cylinder head bolts

|

It was expensive, naturally, and Lotus paid for it out of

its own resources; but about Ł5 million is small change compared with what

most major manufacturers quote for an entirely new motor. It helps that

Lotus engineering is a small team, by Ford or GM standards, of bright, resourceful

engineers; one example is the development of 618's OBD II compliant engine

management, built and made for Lotus by a supplier, but conceived and largely

designed by a team of four Lotus people.

A major example of supplier involvement is in the engine's weight. It scales 210kg dry, including air conditioning compressor, power steering pump and alternator. Thatôs only 15 per cent more than the 2.2-litre Esprit motor - thanks largely to high quality, thin-wall casting (down to 3 mm) from Zeus Aluminium Products of Dudley, Worcestershire. Zeus also casts the bearing ladder of Roverôs KV6 and, according to John Owen, senior project manager for the V8, is todayôs leader in aluminium casting.

Finally, like the fascinating, bonded

aluminium extrusion chassis of the Lotus Elise, Lotus wouldn't mind - if

the price was right - selling the new V8 or the several variations it offers

to a larger manufacturer interested in adopting it, as a power unit of its

own, for niche models. It can be stretched to four litres by increasing

the bore by 3mm, for instance. And Lotus talks of obvious scope for an intercooler

and variable valve timing, neither of which is employed on this first version.

|

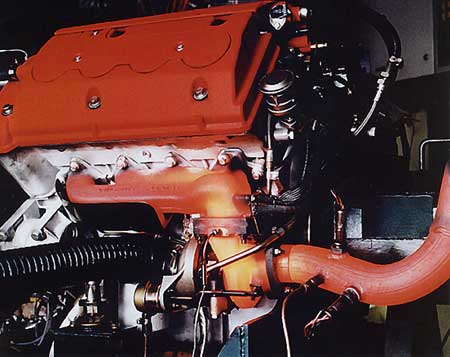

Road car runs 10psi boost for 350bhp. Each Garrett

T25 turbo boosts opposite inlet bank to balance engine. Power injectors

boost max-bhp

|

Owen is modest about the engine's design character. 'A major

part of the concept was high confidence - taking mostly current practices

and re-introducing them in a better package. We have taken a lot of current

technologies and thrown them up in the air. This is not at all a revolutionary

engine.' True, but it is a fine example of the sort of clear, plain thinking

displayed by Keith Duckworth in the original Cosworth DFV.

The packaging of Project 618, a 90deg vee, is impressively

tight, fitting into space 579mm long, 617mm wide and 610mm high. That means

it would slot transversely into a Ford Mondeo; or longways in a rear-drive

car, where its highest point, the throttle body, being at the rear would

allow a pretty low bonnet line. Although not as short (by 133mm) as Rover's

compact KV6 - also a 90deg engine but one litre smaller and with one fewer

cylinder per bank - it is 64mm narrower and 45mm lower.

Any car engine designed for high specific power needs a

stiff, strong base. So all major castings for this engine are in the LM25

TF high-silicon aluminium alloy used by most light-alloy engine makers,

certainly in racing.

Main bearing caps are cast iron, however, cross-bolted as well as normally bolted. The forged steel flat-plane crankshaft sits within crankcase skirts, extended 68mm below the crank centre line, which are in turn closed by a stiff sump casing.

So far, so conventional, albeit racing conventional. The interesting difference is in how Lotus has seized on the way that the vee is used to gain some extra bottom-end reinforcement. Part of the design from the start and not a development fix, this takes the shape of an extra outside wall to each crankcase skirt, slenderly triangulating the space between skirt bottom edge to about halfway up the cylinder block, and formed in a slightly waving profile lengthwise. Lotus says that as well as increasing torsional stiffness, this added at least 30 per cent to beam stiffness.

|

Hydraulic tappets safe to 8600rpm, 500bhp-plus |

Following standard Lotus thinking, the design brief included the demand that no mounting or bracket should be added unless it did at least two jobs. The same applied to the extra crankcase wall, whose inner spaces, combined with casting-core support holes I the inner skirt, provide inter-crank bay breathing, often found in other vee engines by using part of the inter-vee space.

That prompted a further thought. Although the production engine is rev limited (using injection cut-off) to 7000rpm, the hydraulic tappet valve gear is safe to 8600rpm. Such speeds demand more than usually efficient crankcase breathing and, most important, oil separation. So the floor of the inter-vee space, suitably roofed, could be used to offer a calm, sealed space into which crankcase fume could be led (from each end of the crankcase) to drop its load of mist-borne oil for return to the sump.

'The brief included a demand that no bracket should

be added

unless it did at least two jobs'

As Owen says: 'The whole thing in crankcase ventilation is to keep velocities down to a minimum, then you'ôll drop the oil - so you want big chambers. We haven't had even a teaspoonful of carry-over oil throughout all our testing.'

The crankcase has open decks, with each wet cast iron liner located by a shoulder halfway down, Loctited in. As with the KV6, to provide tensile support against cylinder load, cylinder heads are held by 10 high tensile bolts, 260mm long and 11mm in diameter, fully threaded to even out tightening stresses, which end close to the main bearing area. Head castings carry the chill-cast, ductile-iron camshafts acting directly on hydraulic bucket tappets with single coil springs.

Like a diesel, the head gasket is a multi-layer steel type, helping contain a peak brake mean effective pressure of 206psi derived partly from 10lb of boost acting on 8:1 compression. Each bankôs Garrett T25 turbocharger blows into the opposite bank's inlet plenum and 375mm-long runners, which helps keep the engine dynamically balanced should one bank deliver more than the other. Valves, set at 41.5deg included angle, have 33mm (inlet) and 28mm (exhaust) head diameters.

|

Big valves, but no variable valve timing

for V8 |

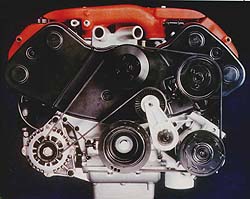

Double overhead cam engines are inherently wide, so it is useful to keep the outer camshaft drive wheels from adding width. So Lotus put the 1:2 gearing, with its large diameter driven wheel required for timing drive, within the engine, using a Borg-Warner chain driven off the crankshaft inboard of the concentric-type oil pump. Each pair of camshafts has itôs own 1:1 belt drive.

At launch, the belts are conventional Goodyear toothed type, but they were to have been Goddyear's new helical offset tooth (HOT) belt, whose self-aligning does away with the need for belt guides. Drive to the alternator, water pump, air conditioning and power steering pumps is by a separate serpentine belt outboard of the timing drive, so that if, for example, the water pump misbehaved, its seizing would not cause a catastrophic stopping of the camshaft drive.

Owen has strong views on keeping water pumps out of timing drives: 'People who mix them should be shot.' The injection system is similar to that which feeds the four-cylinder Esprit turbo engine. Partly because no production injectors could be found to give more than just under 3gm per sec flow rate - not enough fuel for maximum power - Lotus uses an extra pair of power injectors, placed just after the throttle body in the plenum chambers, which come in when needed.

|

On-board diagnostic developed

for US market |

As on the four-cylinder engine, the top-end boost these provide is claimed to be party because of the charge-cooling effect of evaporating fuel. All threads are rolled, not tapped. As well as increasing strength, this also avoids the notoriously clinging corkscrew swarf of tapping, which is difficult to clean out completely from engine castings.

Lotus will be able to make up to 500 a year: a dedicated plant could turn out 10.000. For now, though, the first concern is the GT1 series baptism of fire at Paul Ricard, where a 500bhp-plus full racing version, with dry-sump lubrication, intercooled with 15psi of boost, will carry the Lotus's hopes.

The production Esprit V8 should be no sluggard; Lotus claims at 4.2sec 0-60mph and a top speed of at least 170mph. In ordinary driving, the biggest everyday gain, apart from refinement, should be flexibility: above 2000rpm, this engine never produces less than 230lb ft of torque.

Currently, Lotus has 'about half a dozen' four-cylinder 2.2-litre Esprits left. Once they are sold, the 2.2-litre disappears. There'll be a cheaper base model Esprit in early 1997, under development at the moment, with the adoption of a two-litre Esprit turbo engine. But until then, it's down to the new V8 to keep the Esprit's head out of water. We wish it well.

SPECIFICATION

| Layout | 90deg V8, twin turbocharged |

| Capacity | 3506cc |

| Max power | 350bhp at 6500rpm |

| Max torque | 295lb ft at 4250rpm |

| Specific output | 100bhp/litre |

| Max bmep | 253gm/kW hr (0.381lb/hp hr) |

| Made of | alloy heads and block |

| Bore/stroke | 83/81mm |

| Compression ratio | 8.0:1 |

| Cylinder centres | 96mm |

| Cylinder liners | wet, cast iron, mid-hung |

| Block height | 215mm (crank to head face) |

| Head gasket | multi-layer steel |

| Valves | 4 per cyl, dohc, hydraulic tappets |

| Valve angle | 41.5deg included |

| Valve head size | 33.3mm inlet, 28.3 exhaust |

| Valve lift | 9.0mm inlet, 8.15mm exhaust |

| Camshaft drive | chain/toothed belt |

| Crankshaft | forged steel, flat plane |

| Main/big end bearings | 65/47mm diameter |

| Small end bearing | 21mm diameter |

| Turbochargers | 2 Garrett T25, non-intercooled |

| Injectors | Port (8) plus 1 per plenum |

|

|